Manual of use for ThermaNin

Introduction

Thermal paper, once mainly used as fax paper only, is now used in many applications. These days it is used in ticket dispensers for giving out waiting number or parking tickets, in label printers, and printers for point-of-sales receipts at retail shops like supermarkets.

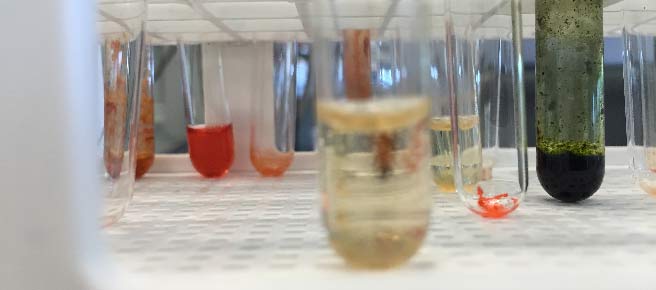

Thermal paper turns black on application of heat (as in the printer) but also on contact with polar solvents like alcohols, acetone, ether, ethyl acetate etc. The regular solutions of fingerprint reagents like ninhydrin and DFO are either based on a polar solvent (ninhydrin in ether or acetone for example) or rely on certain amounts of these polar solvents to dissolve them when used in an apolar bulk solvent like petroleum ether or heptane.

These solutions have a detrimental effect on thermal paper: on application the paper surface turns dark grey or black thereby obscuring any fingerprints that may subsequently develop.

Techniques for developing fingerprints on thermal paper

There are a number of techniques known for developing fingerprints on thermal paper:

- 1,2-IND has been reported in several publications [1-3] to develop fingerprints without darkening the top (active) layer of the thermal paper. For finding and photographing the developed prints a Polilight or similar light source is needed.

- DMAC (dimethylaminocinnamaldehyde) fumes react with fingerprints on thermal paper [4]. The fluorescence of any developed prints can be photographed with green light (Polilight, around 530 nm).

- Exposure to the fumes of concentrated hydrochlorid acid was reported to develop prints on the top layer of thermal paper [5]. It will not develop prints on the back of thermal paper.

- Rinsing away the thermal layer with acetone first and then treat with a regular ninhydrin solution. Alternatively treating the items with ninhydrin solution and after allowing ample time for development of fingerprints, rinsing the paper with an excess of acetone to remove all the text and/or grey-black stains. [6]

- Ninhydrin sublimation in a vacuum [7].

- Application of low-temperature heat [8a-c].

These techniques may not be appropriate, or the additional equipment needed not available.

Japanese researchers have published [9] that hemiketals of ninhydrin, obtained by exchanging the water molecule in ninhydrin [also known as 1,2,3-indantrione monohydrate] for an alcohol, are soluble in apolar solvents like petroleum ether without the need for addition of polar solvents. The solutions were reported to develop fingerprints on thermal paper, without darkening of the surface.

Such a product is ThermaNin.

To our knowledge, the effectiveness of the different techniques has not been compared.

How does ThermaNin work

ThermaNin will not develop any fingerprints by itself. The process relies on the fact that after application of its solution to paper, ThermaNin will readily convert to ninhydrin and the alcohol upon contact with water present in the paper or in the atmosphere. This conversion can be detected from the weak odor of the alcohol that will be given off by the paper afterwards. The ninhydrin will then be available to react with any fingerprint residue in the paper. The ninhydrin will not dissolve in petroleum ether, so the paper can be dipped twice (with a certain waiting time in between, to allow for the conversion of the ninhydrin hemiketal to ninhydrin and alcohol) to increase the ninhydrin concentration in the paper.

Manual of use

Due to the sensitivity of ninhydrin hemiketals (like ThermaNin) towards water, their solutions in petroleum ether cannot be stored long without degrading the performance. A working solution should be used soon, at least within 1-3 weeks. Therefore, we cannot supply working solutions, they should be made fresh when needed. The ThermaNin crystals that we supply are fairly resistant to atmospheric humidity and have no apparent shelf life when stored in tightly sealed containers.

A working solution that takes not too long to prepare, by dissolving the ThermaNin powder in petroleum ether/pentane or heptane by shaking (for 5-10 minutes), contains 4 gram per liter (or 0.4 gram per 100 ml). Slight warming of the solution (till around 30-40° C) will aid the dissolution of the ThermaNin powder considerably. Adding 0.5 ml of isopropanol (and optionally 1.5 ml of ethyl acetate) per 100 ml of solution helps a lot too (see further for notes on stability).

Contrary to our expectations, ThermaNin was found to have a very low solubility in HFE-7100. Therefore working solutions of ThermaNin cannot be made in HFE-7100 alone. However, preliminary experiments [July 2004] indicate that stable solutions, even in glass bottles, can be made by adding 0.5% isopropanol and 1.5% ethylacetate as co-solvents. This solution does not color the active layer of thermal paper.

A working solution can be made quickly, by weighing 0.4 to 0.5 gram of Thermanin and adding this to an empty 100 ml bottle (glass or aluminium). Adding 0.5 ml of isopropanol and 1.5 ml of ethylacetate will dissolve the Thermanin, subsequently dilute to 100 ml by adding the HFE7100.

German researchers at the BKA in Wiesbaden found that for dissolving, application and storage of working solutions of ninhydrin hemiketals either plastic or aluminium containers should be used, with a strong preference for aluminium. Generally speaking petroleum ether etc. diffuses out of plastic bottles and water in, aluminium does not have this problem.

In glass bottles the shelf life of the working solutions is drastically shortened. This is probably due to the small amount of water adhering to the walls and the slightly acidic nature of the glass surface (accelerates the reaction between water and ThermaNin). However, adding 0.5% of isopropanol (5 ml per liter) stabilizes the solution without negative effects on the thermal paper.

Development of the fingerprints can be done in the usual manner: at room temperature, in the dark and elevated humidity (around 80% is preferred). Because of the nature of thermal paper heating of the paper to accelerate development of the prints is not possible: the paper will turn dark.

Because of the sensitivity of the paper for polar solvents, treatment of the thermal paper with zinc chloride is not an option either.

A stable working solution, even in glass bottles, has the following composition:

4-5 g ThermaNin crystals

5 ml isopropanol

15 ml ethyl acetate (optional for petroleum ether/heptane based solutions)

980 ml petroleum ether (60-80°), heptane, or HFE-7100

--------

1000 ml working solution

Safety

On contact with water ThermaNin will readily fall apart in ninhydrin and alcohol. Therefore, the safety characteristics of the product can be judged from those components. Ninhydrin is considered harmful if swallowed and irritating to eyes, skin and respiratory system; the alcohol as a skin and eye irritant. The precautions taken when working with ninhydrin (protective clothing, gloves, safety glasses when working with the solutions) will be sufficient for this product too.

References and footnotes

[1] Stimac, J.T., "Thermal Paper: Latent Friction Ridge Development via 1,2-Indanedione", Journal of Forensic Identification, 2003, Vol. 53, No. 3, p. 265-271.

[2] Stoilovic, M.; Lennard, C.; "Fingermark Detection & Enhancement", Workshop Manual, National Centre for Forensic Studies, 6th Edition, 2012.

[3] Goel, T.L., "Developing Latent Fingermarks on Thermal Paper: Comparison of the 1,2-Indanedione-Zinc Chloride Dry Contact Method to the Hot Print System.", Journal of Forensic Identification, 2015, Vol. 65, No. 1, p 34-43.

[4] Brennan, J.; Bramble, S.; Crabtree, S.; Wright, G.; "Fuming of Latent Fingerprints Using Dimethylaminocinnamaldehyde", Journal of Forensic Identification, 1995, Vol. 45, No. 4, p. 373-380.

[5] Broniek B.; Knaap, W.; "Latent fingerprint development on thermal paper using muriatic (hydrochloric) acid", Journal of Forensic Identification, 2002, Vol. 52, No. 4, p. 427-432.

[6] Fingermark Visualisation Manual, Chapter 5.TCR ISBN: 978-1-78246-234-7, Home Office, January 2014. Available from The Stationary Office.

[7] Schwarz, L.; Frerichs, I., "Advanced Solvent-Free Application of Ninhydrin for Detection of Latent Fingerprints on Thermal Paper and Other Surfaces", Journal of Forensic Sciences, 2002, Vol. 47, No. 6, p. 1274-7. DOI: 10.1520/JFS15559J

[8a] Wakefield, M.; Armitage, S.; "The Development of Latent Fingerprints on Thermal Paper Using a Novel, Solvent-Free Method", Journal of Forensic Identification, 2005, Vol. 55, No. 2, p. 202-213.

[8b] TFD-2 Thermal Fingerprint Developer, made by Foster and Freeman.

[8c] HPS, made by Consolite Forensics.

[9] Takatsu, M.; Kageyama, H.; Hirata, K.; Akashi, S.; Yoko Ta, T.; Shiitani, M.; Kobayashi, A. "Development of a New Method to detect latent fingerprint on thermal paper with O-Alkyl derivate of ninhydrin", Reports of the National Research Institute of Police Science, 1991, Vol. 44, No. 1, p. 1-6.