History

The Physical Developer as now used in the forensic field originates from a formulation published in 1969 by Dutch researchers from the Philips Research Laboratory in Eindhoven, the Netherlands [1] who where researching developers for photographic film. J.R. Morris working under contract of the Police Scientific Development Branch (PSDB) at the Atomic Weapons Research Establishment (AWRE) at Aldermaston, England recognized it's potential as fingerprint reagent and the first one to report about it in 1975. His recipe, mostly unchanged to this day, has minor changes compared to the FC1-recipe described by the Philips researchers.

According to Antonio Cantu and James Johnson (Chapter 7 in Advances in Fingerprint Technology, 2nd edition [2]) Sheila Hardwick of the PSDB was responsible for getting PD into the police laboratory by writing an operating manual for it (circa 1984). The Forensic Division of the US Secret Service (Cantu and later Robert Ramotowski amongst others) has done or have been involved with a great deal of research into PD and also in promoting it's use in lectures and workshops at conferences (see e.g. references 3-7).

The formula that replaces Synperonic N (a nonylphenol ethoxylate that is being phased out for environmental reasons) with Tween 20 was pioneered by the US Secret Service [3].

The understanding of the PD process is that the silver ions (Ag+) in the Fe2+, Fe3+ mixture wants to become oxidized to silver (Ag) at the expense of Fe2+ (becoming Fe3+). This starts to happen when you mix the silver nitrate solution to the bulk solution with the iron salts but the silver particles that are formed get stabilized by the surfactants (N-dodecylamine acetate and Synperonic N [8] or N-dodecylamine acetate and Tween 20 depending on the recipe) and the process stops.

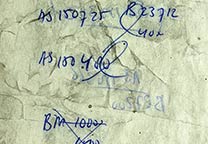

Fingerprint residue (or other sites like scratches in the glassware, folds in the paper, staples) attracts those stabilized silver particles and they then in turn iniate the deposit of more silver particles is the theory. The silver particles look a bit like pompoms under an electron microscope. The deposited particles in bulk appear black (like black and white prints in classic photography.)

Directions for use

Working solution should be prepared 1-3 days in advance for best results. Add the silver nitrate solution to the redox solution and mix by swirling or shaking. If you don't want to make up that much solution, measure out the appropriate amounts (95 ml of redox solution for 5 ml of silver nitrate solution) and add to a clean bottle (a brown glass bottle is best, than you can see if there is a precipitate forming when the solution gets bad.)

The processing can be done in one tray or several trays and the papers taken from one to the other. The trays can't be metallic (glass or plastic, however polycarbonate appears not to work well) and the processing tray (silver depositing) should be free from scratches and rinsed with distilled or RO/DI water before use. Scratches also cause silver to precipitate!

Step 1: the papers to be processed should first be rinsed in a tray containing distilled water (using reverse osmosis-deionized = RO-DI water is best for the whole process) to remove dust, Ruhemann's purple and/or other water soluble compounds. The tray should be agitated (lightly rocking the tray) for at least 5 minutes.

Step 2: either pour the distilled water out of the tray for the next step or transfer the paper to the next tray with the acid prewash solution. For the transfer only tweezers with smooth surfaces can be used. If they have grooved surfaces the pattern will show in the processing step!

The acid prewash step is needed to neutralize alkaline substances e.g. chalk in the paper. These alkaline materials would cause severe background staining due to silver precipitation. The prewash takes about 10 minutes but longer if there are still bubbles developing on the surface of the paper. This step is very important since if not done long enough it can cause severe background staining of the paper, obscuring the prints. The acids most often used in this solution are either maleic acid or malic acid in a concentration of 25 grams per liter. However, nitric acid and acetic acid (vinegar) can also be used [7]. Hydrochloric acid can absolutely not be used. The chloride would react with the silver ions in the next step causing background staining.

Step 3: either pour the acid prewash out of the tray or transfer the paper to the processing tray that contains the iron salts solution mixed with silver nitrate solution. Research [3] has found that the mixing of the solutions should be done at least 24 hours to 72 hours prior to using it to get the best results. In this step, as in the previous steps, the tray should be lightly rocked during the process to keep the solution uniform. The items should not be left unattended. Prints can show up in a matter of minutes or up to an hour (mostly around 10 minutes) and processing should be stopped when the background staining starts to deterioate the contrast between prints and paper or the development doesn't improve any more.

Step 4: the papers should be rinsed with water to remove any trace of the working solution (this would stain the paper after drying). Although tap water could be used (in a separate dish) it is the safest to use RO-DI water. Tap water might leave chlorine salts in the paper that would be detrimental in case a second treatment with PD is tried later.

Step 5: blotting the paper dry and air dry them. Elevated temperatures may be used.

Composition of solutions

Pre-wash solution:

Dissolve 25 g of malic acid (CAS-number: 110-16-7) or malic acid (CAS-number 6915-15-7) in 1 liter of RO-DI water with a magnetic stirrer bar (teflon coated magnet.)Redox solution:

To 900 ml of RO-DI water stirred with a magnetic stirrer bar add the following compounds in the order mentioned. Allow the compounds to dissolve completely before adding the next.

30 g iron(III) nitrate nonahydrate (Fe(NO3)3.9H2O, CAS-number [7782-61-8])

80 g ammonium iron (II) sulphate hexahydrate (Fe(NH4)2(SO4)2.6H2O, CAS-number [7783-85-9])

20 g citric acid, CAS-number [77-92-9])

Detergent solution:

3 g N-dodecylamine acetate, CAS-number [2016-56-0], and

3 ml Tween 20 are added to 1 liter of RO-DI water and stirred (magnetic stirrer) till the dodecylamine acetate is dissolved (the solution will appear hazy).

Silver nitrate solution:

10 g silver nitrate (AgNO3) is dissolved in 50 ml of RO-DI water (dissolves easily, swirling the solution till the silver nitrate is dissolved will suffice.)

Working solution:

Add to 900 ml redox solution and mix by swirling:

40 ml detergent solution and then

50 ml silver nitrate solution.

In the solutions we provide the detergent solution and redox solution are pre-mixed. Adding the silver nitrate solution should be done 1-3 days in advance for best results. The solutions can be used for several weeks (up to about 8 weeks). If a milky white precipitate starts to develop at the bottom of the bottle the solution should be discarded.

Solution that has been in a tray and not exhausted yet can be kept for later use. However, it should never be added back to the bottle with fresh solution but kept in it's own (labeled) bottle.To check if a solution (still) works properly the Forensic Division of the USSS developed a test paper [4]. This is made by preparing a solution of 1 gram of EDTA tetra sodium salt dihydrate (CAS-number 64-02-8) in 30 ml of RO-DI water. Using a micropipette 10 microliter of this solution is pipetted on a piece of filter paper (e.g. Whatman number 2) and the side where the drop was put marked. After drying this test paper is dipped in the working solution for about 1 second and then left outside of the solution to develop a black spot. If it develops in less than 10 seconds the solution works properly.

For a test paper based on ascorbic acid and oleic acid, printed on paper with an ink jet printer see reference 9.

References and footnotes

[1] Jonker, H.; Molenaar, A.; Dippel, C.J., "Physical Development Recording Systems: III. Physical Development", Photographic Science and Engineering, 1969, Vol. 13, No. 2, p. 38-44.

[2] Advances in fingerprint technology / edited by Henry C. Lee, R.E. Gaensslen, second edition, 2001, ISBN 0-8493-0923-9, CRC Press.

[3] Houlgrave, S.; Andress, M.; Ramotowski, R., "Comparison of Different Physical Developer Working Solutions - Part I: Longevity Studies", Journal of Forensic Identification, 2011, Vol. 61, No. 6, pp. 621-639.

[4] Houlgrave, S.; Ramotowski, R., "Comparison of Different Physical Developer Working Solutions - Part II: Reliability Studies", Journal of Forensic Identification, 2011, Vol. 61, No. 6, pp. 640-651.

[5] Burow, D., "An Improved Silver Physical Developer", Journal of Forensic Identification, 2003, Vol. 53, No. 3, pp. 304-314.

[6] Burow, D.; Seifert, D.; Cantu, A.A., "Modifications to the Silver Physical Developer", Journal of Forensic Sciences, 2003, Vol. 48, No. 5, pp. 1094-1100, [doi:10.1520/JFS2003044]

[7] Ramotowski, R., "A Comparison of Different Physical Developer Systems and Acid Pre-treatments and Their Effects on Developing Latent Prints", Journal of Forensic Identification, 2003, Vol. 50, No. 4, pp. 363-384.

[8] Fingermark Visualisation Manual, Chapter 5.PD ISBN: 978-1-78246-234-7, Home Office, January 2014. Available from The Stationary Office.

[9] Kupferschmid, E.; Schwarze, L.; Roux, C., "Development of Standardized Test Strips as a Process Control for the Detection of Latent Fingermarks using Physical Developers", Journal of Forensic Identification, 2010, Vol. 60, No. 6, pp. 639-655.